+34 962 801 391

OUR PRODUCTS

TECNOVILL has extensive experience in the design and manufacture of machinery, specialized in the fruit and vegetable sector.

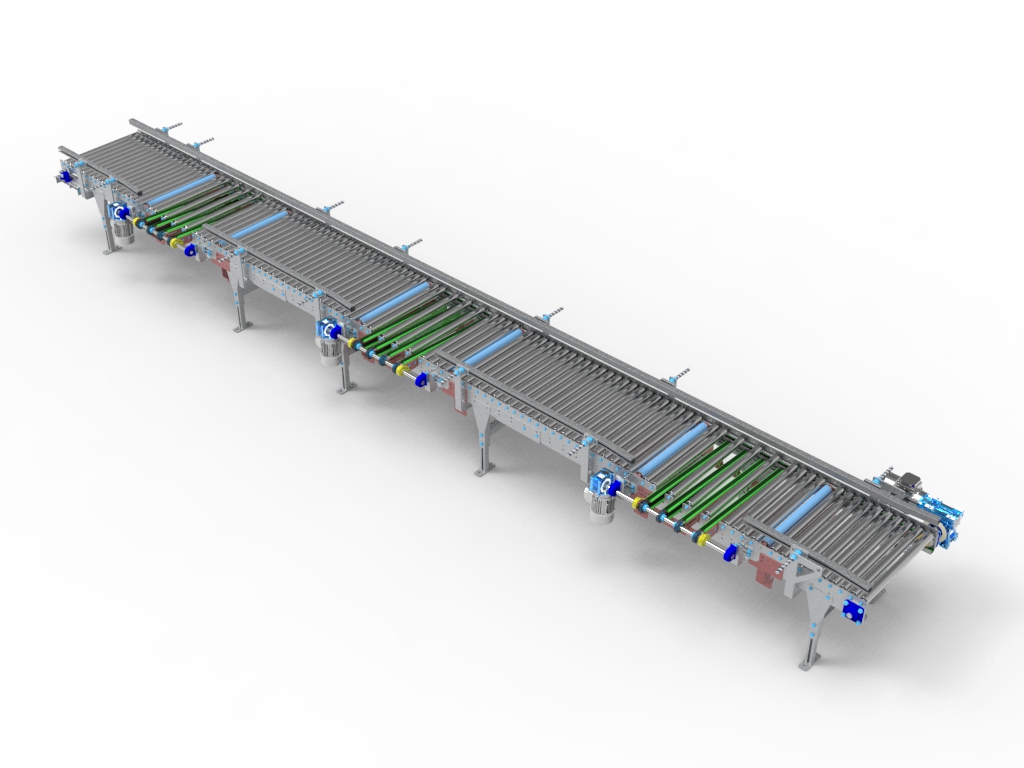

MOTORIZED ROLLER CONVEYOR

MOTORIZED ROLLER CONVEYOR

DESCRIPTION

VIDEO

FEATURES

RELATED PRODUCTS

PDF

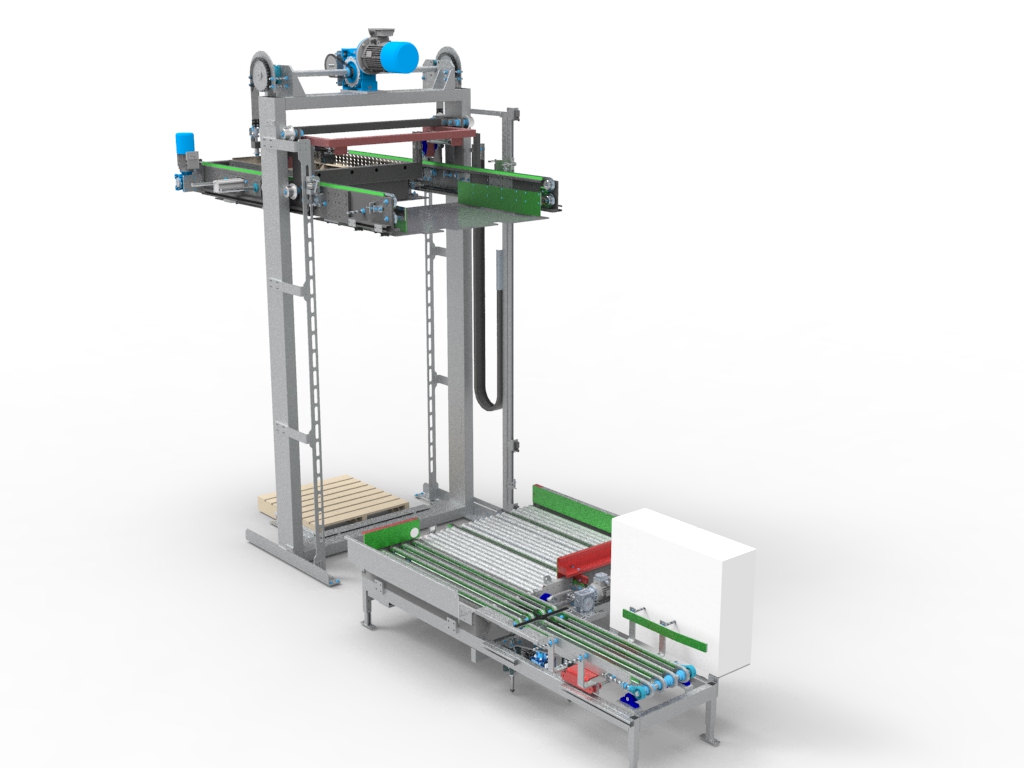

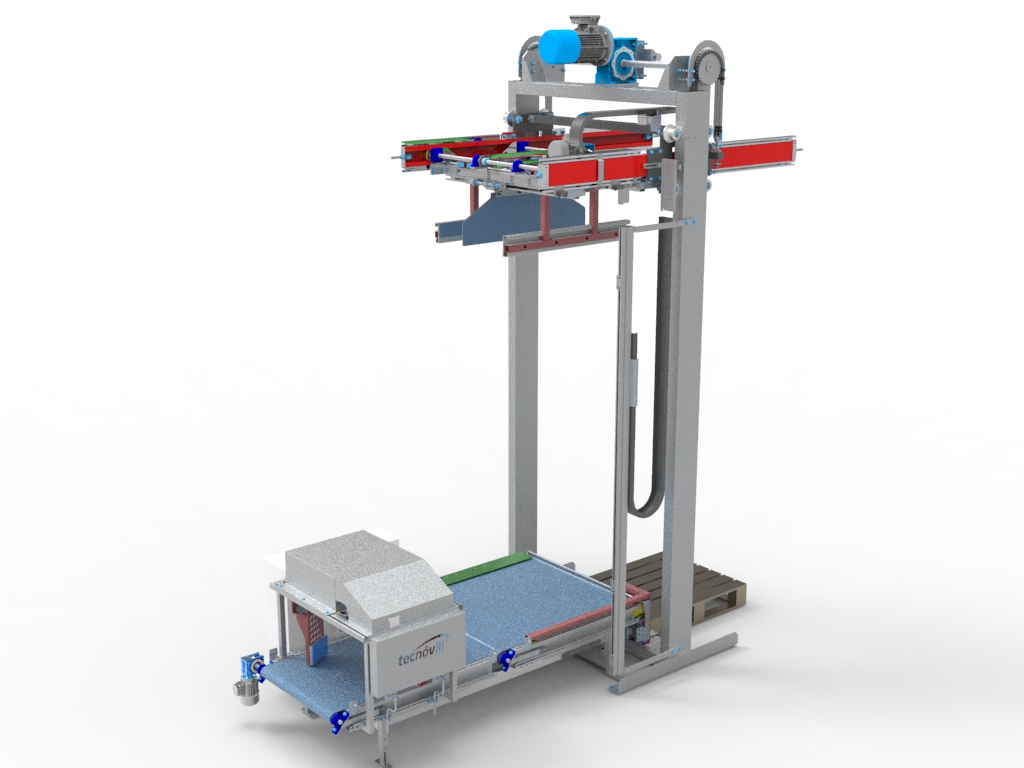

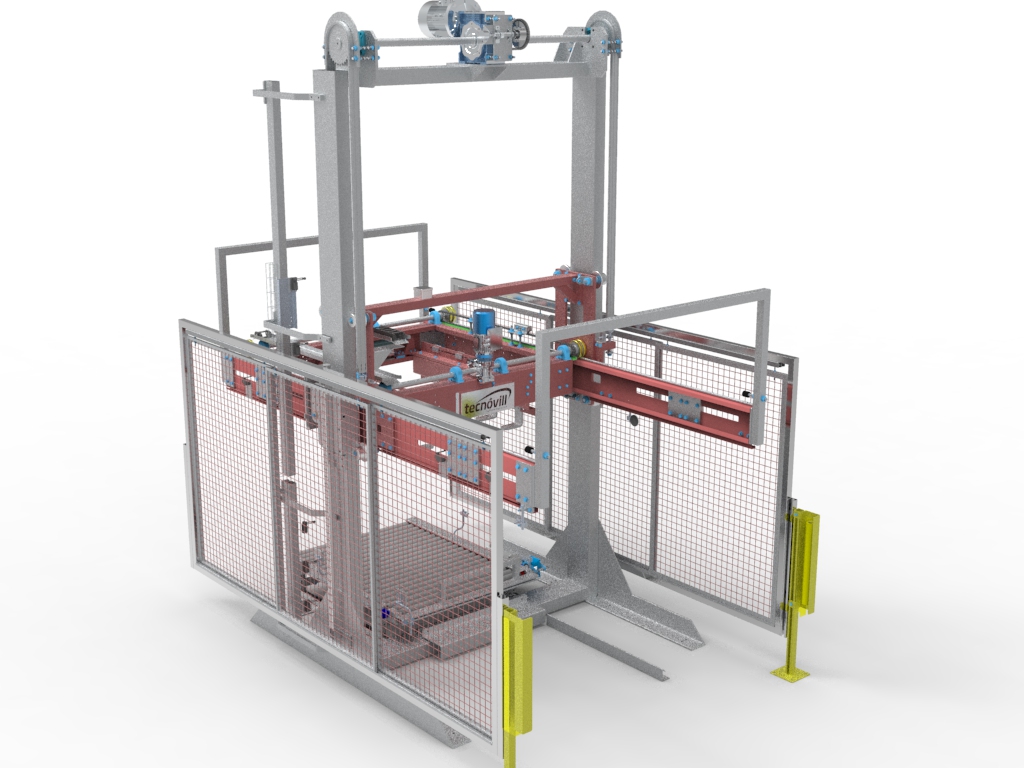

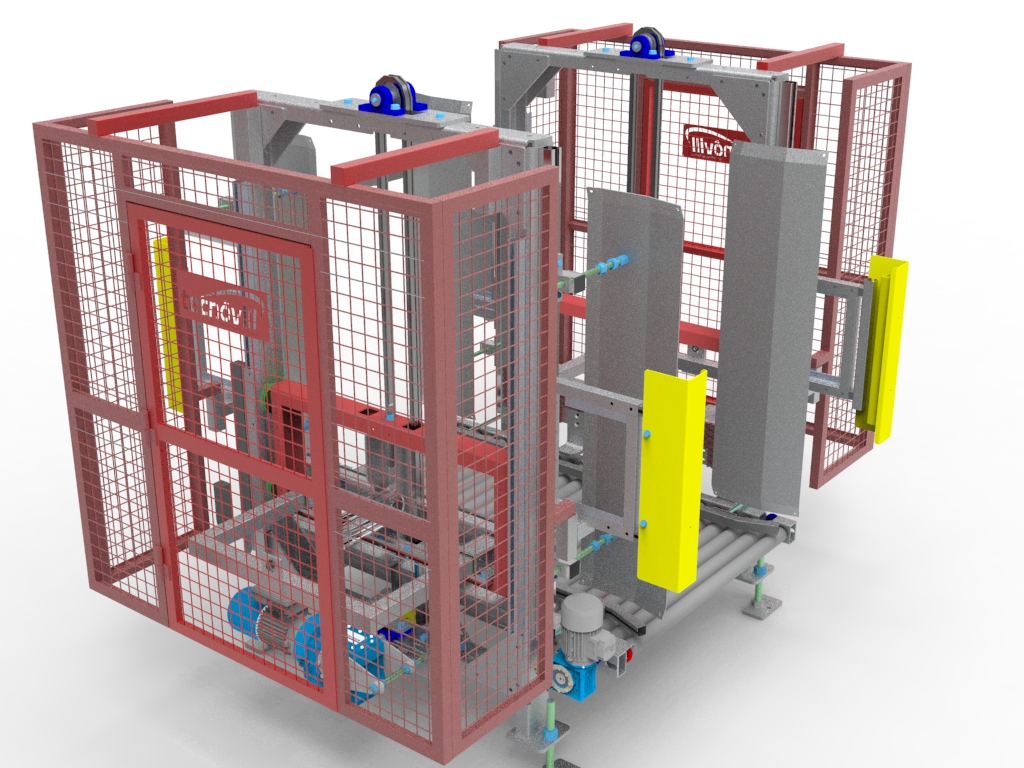

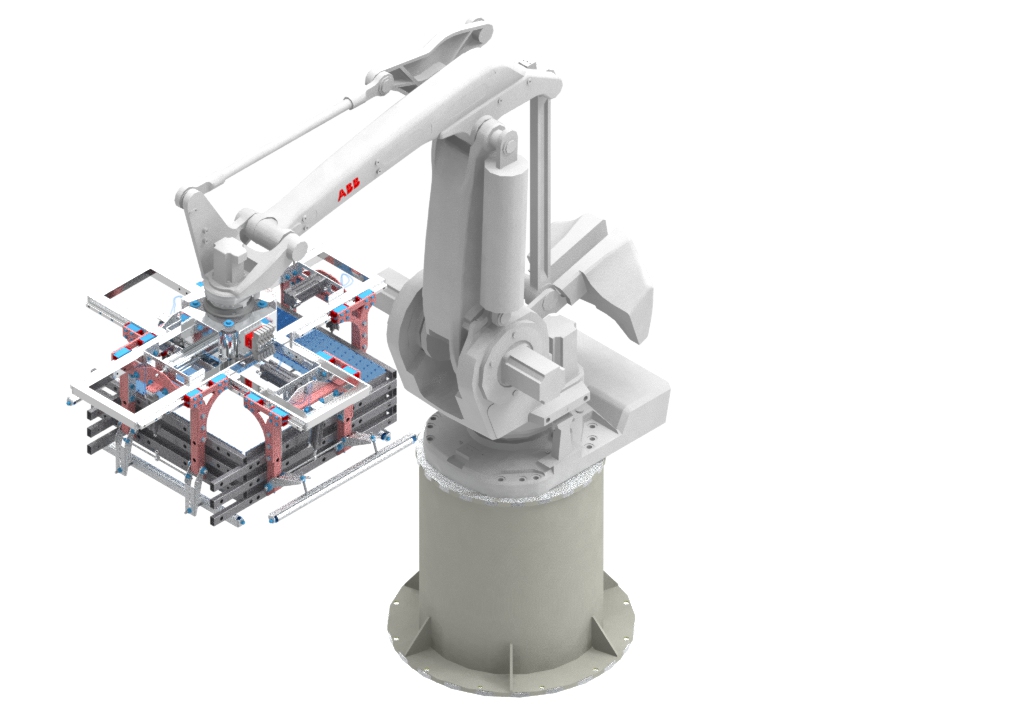

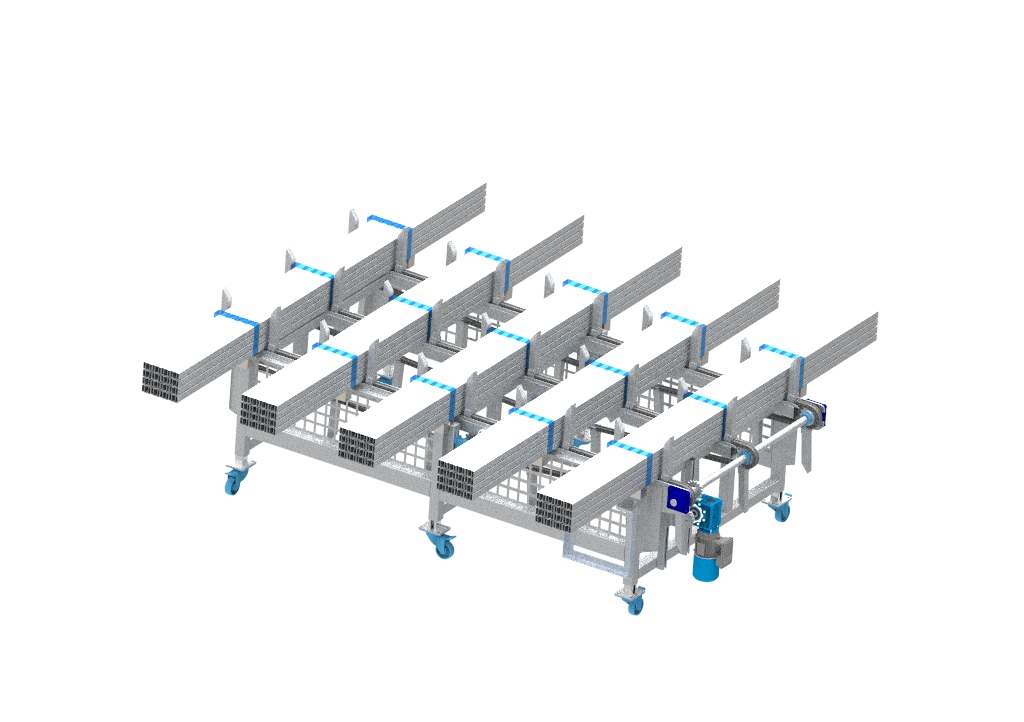

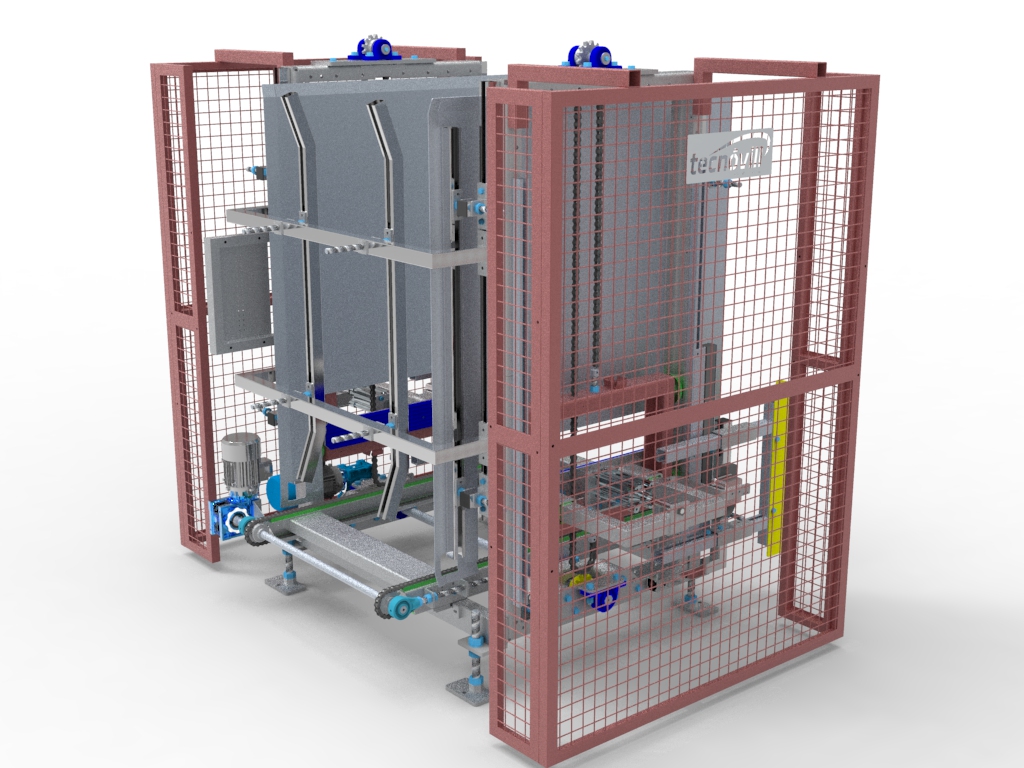

The motorized roller conveyor is designed to dose multiple automated palletizing lines, ensuring smooth and efficient transport of boxes or containers.

Material and Construction:

- Made of high-quality coated steel, meeting European quality standards.

- Durable and robust, designed to support heavy loads, guaranteeing a long service life and reliable performance in demanding industrial environments.

Transport Speed:

- The transport speed can be adjusted according to process needs, allowing precise control of the product flow.

- The speed adjustment is performed via an electronic variator, facilitating adaptation to different types of products and operational requirements.

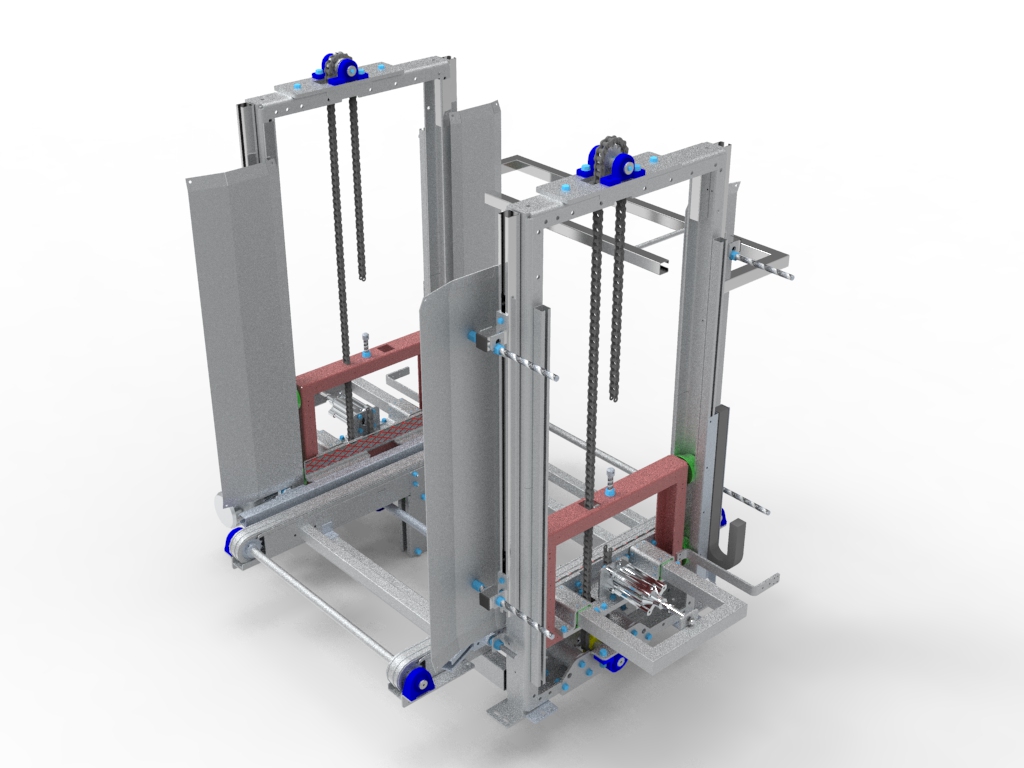

Structure:

- Comprises a continuous movement roller conveyor, with variable width, height, and length according to the user's specific needs.

- The modular structure allows customization and adaptation to different palletizing line configurations.

- Equipped with transfer systems for the entry and exit of boxes, based on the number of palletizing lines.

- Features pneumatic stops to ensure precise stopping of boxes at programmed exits, enhancing process efficiency and safety.

- Optionally, a bar code scanner can be installed for automatic box dosing.

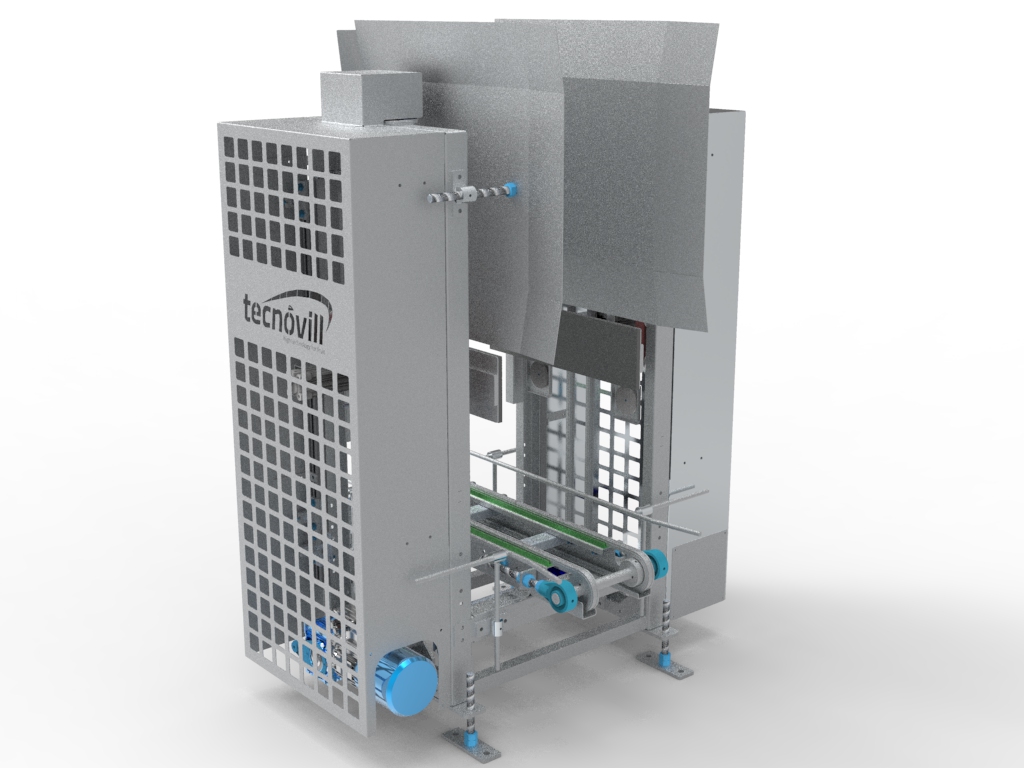

Electrical Panel:

- Equipped with an electrical panel that centralizes all control and operation functions of the machine.

- Includes a touchscreen and control buttons, facilitating easy and efficient operation.

- The user interface is designed to be intuitive and easy to use, allowing quick and precise adjustments of the conveyor settings.

Safety and Maintenance:

- The design of the motorized roller conveyor includes safety measures to protect both the operator and the transported products.

- The machine is designed for easy maintenance, with simple access to all main components, minimizing downtime and maximizing productivity.

Dimensions

| Length (mm) | 7210 |

| Width (mm) | 1150 |

| High (mm) | 750 |

| Weight (mm) | 1185 |

| Area (m²) | 8.29 |

Consumption

| Electric (kW) | 1.11 |

| Air (l/h) | |

| Pressure (Bar) | |

| Gasoil (l/h) | |

| Gas (m³/h) |

ABOUT US

More than 35 years of specialized engineering in the horto fruit sector.

CONTACT US

Telephone: +34 962 801 391

Address: C/ El Parral, nº 10 - 46722 Beniflá (Valencia) España

Email: tecnovill@tecnovill.com

© TECNOVILL Legal notice and Privacy policies.

.jpg)