OUR PRODUCTS

TECNOVILL has extensive experience in the design and manufacture of machinery, specialized in the fruit and vegetable sector.

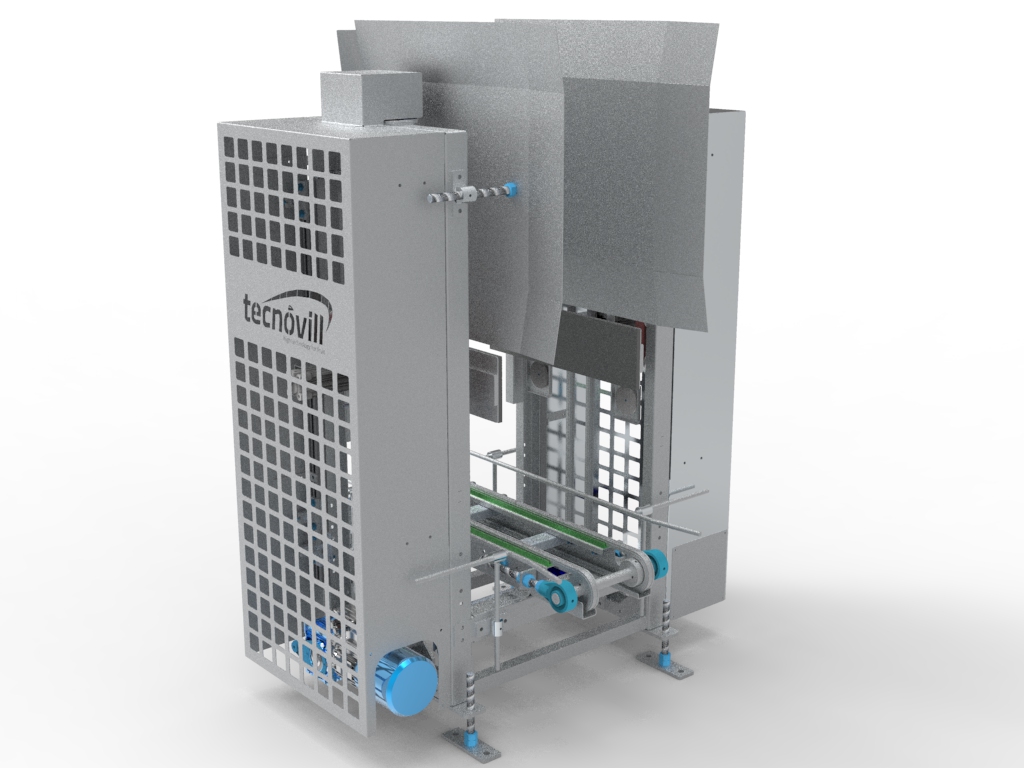

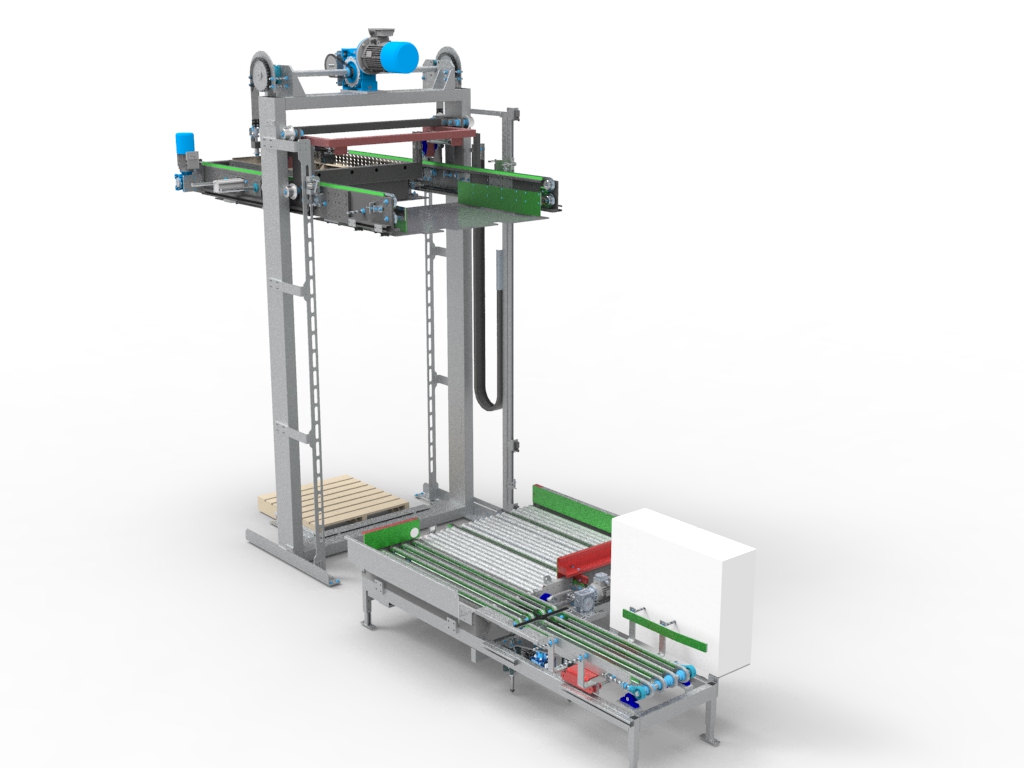

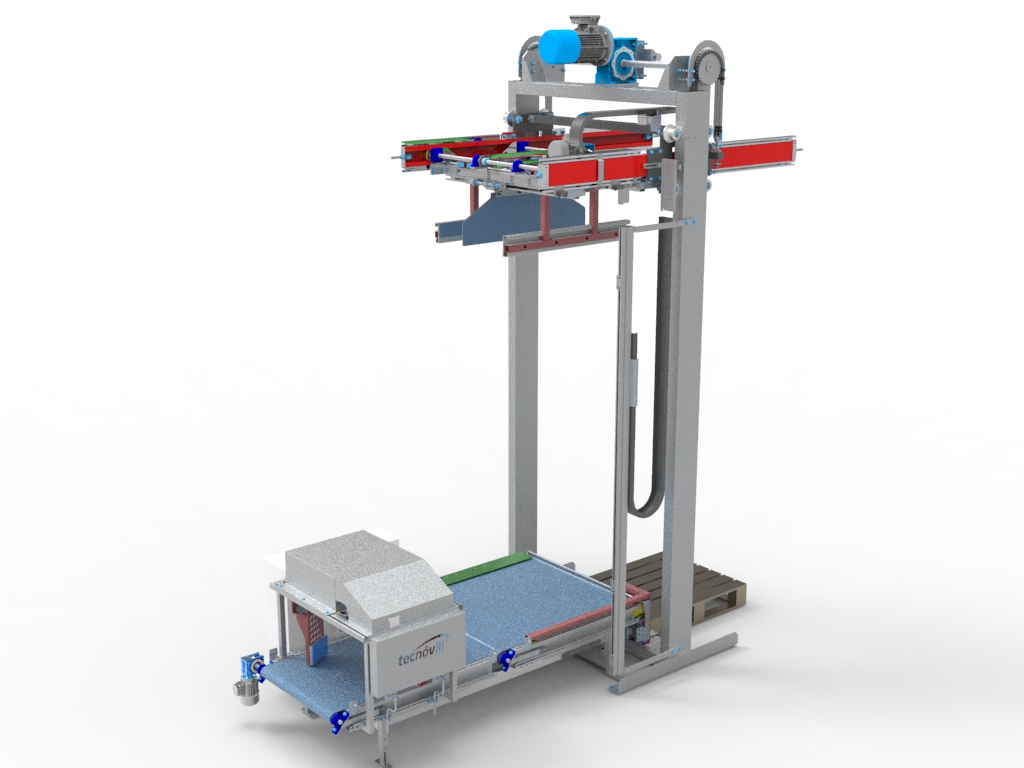

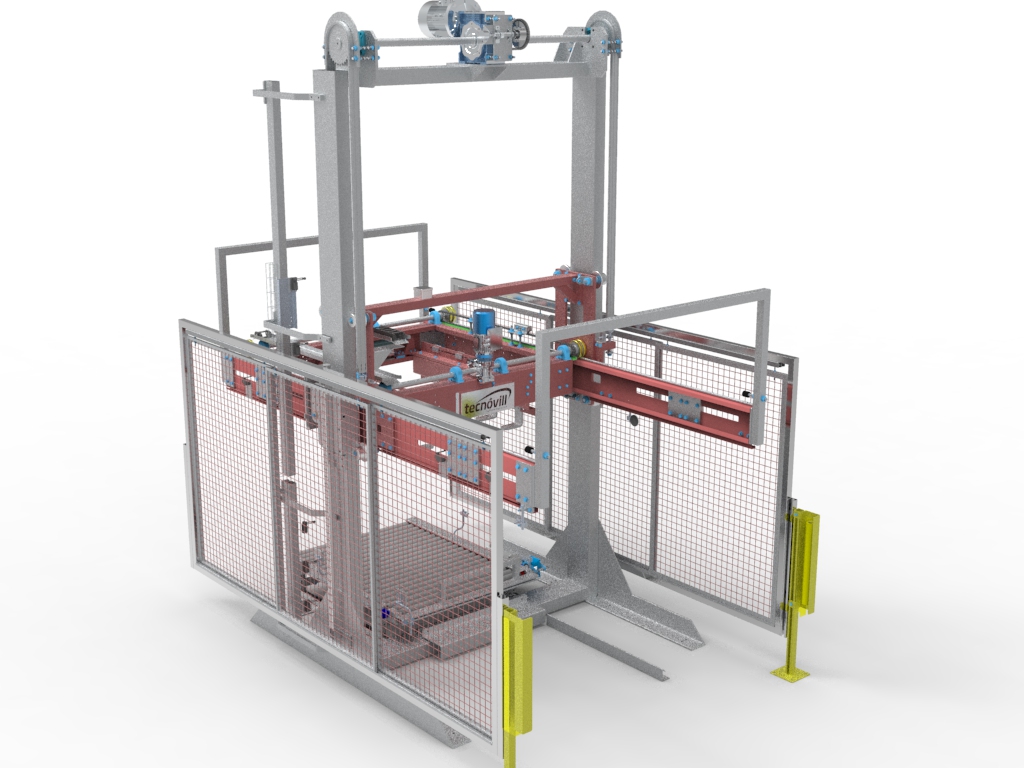

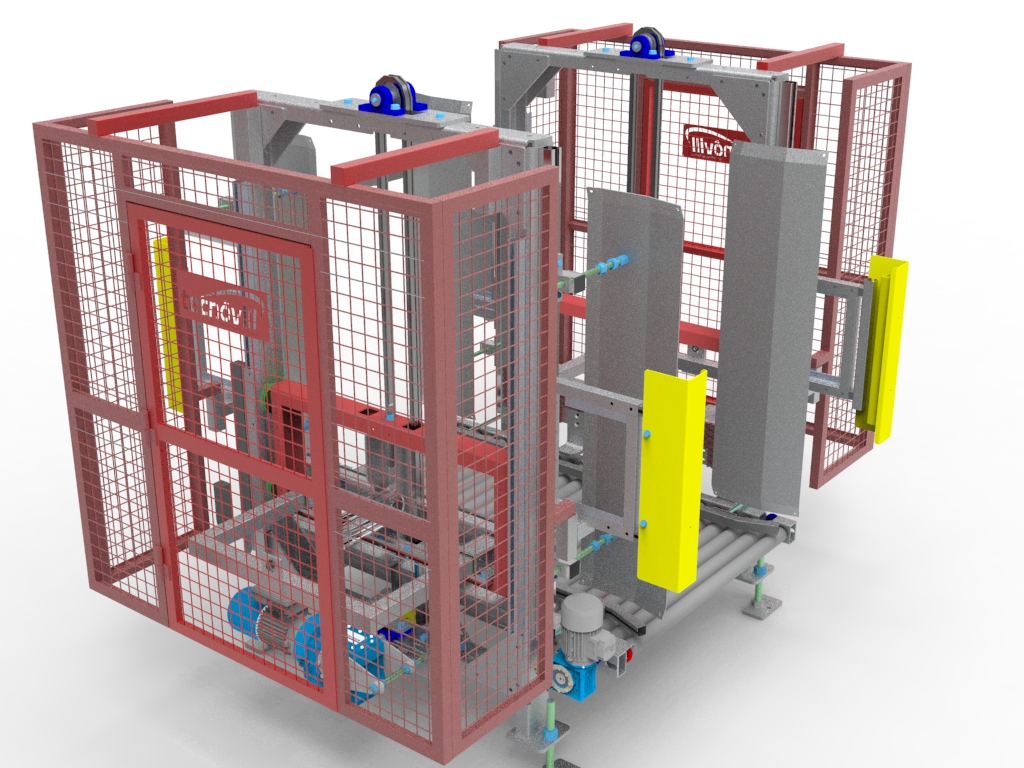

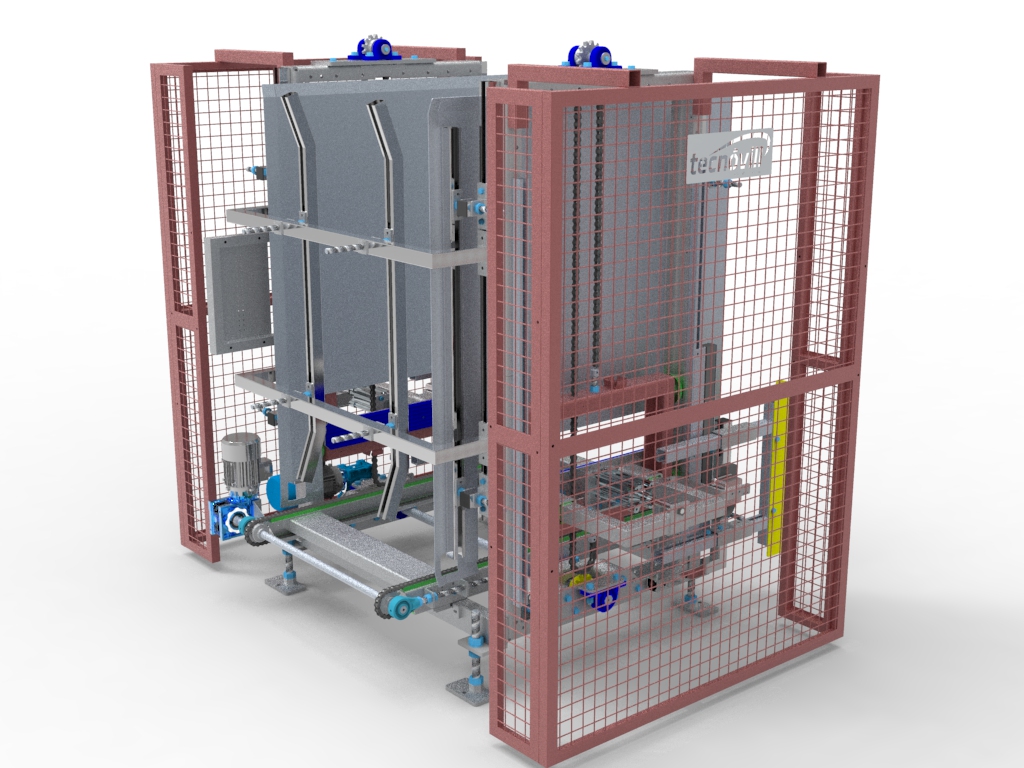

AUTOMATIC BOX STACKER

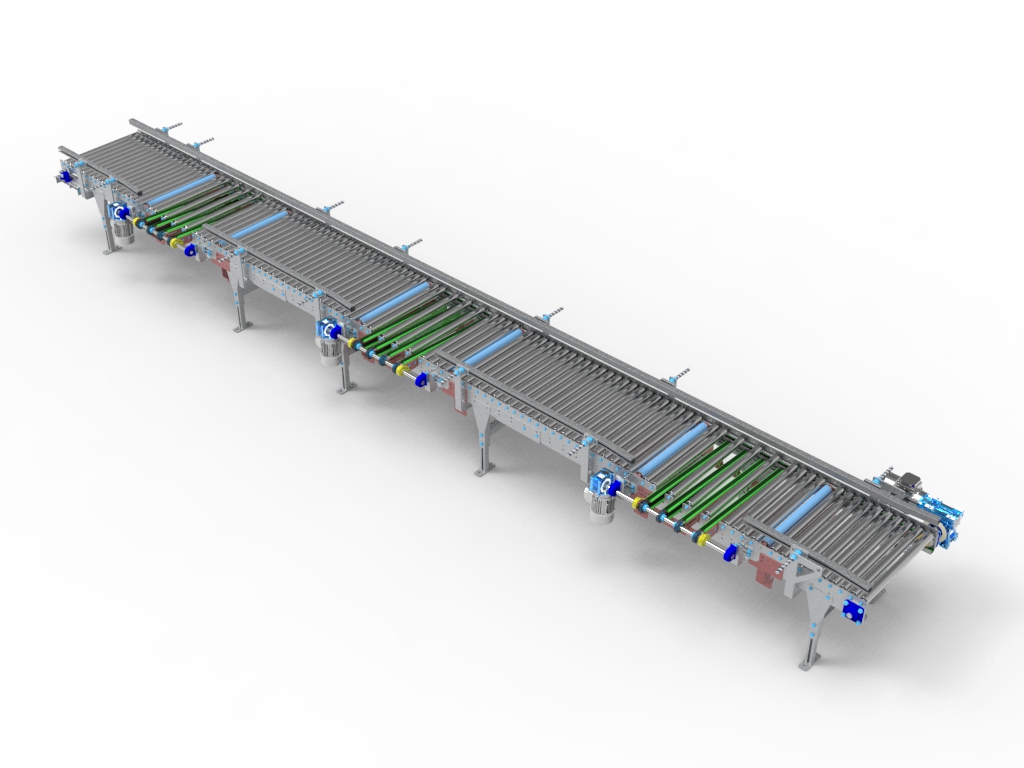

The automatic box stacker is designed for the smooth and efficient transport of boxes or containers in industrial processes, ensuring homogeneous and precise stacking.

Material and Construction:

- Made of high-quality steel, meeting European quality standards.

- Durable and robust, designed to support the necessary loads in these processes, ensuring a long service life and reliable performance in demanding industrial environments.

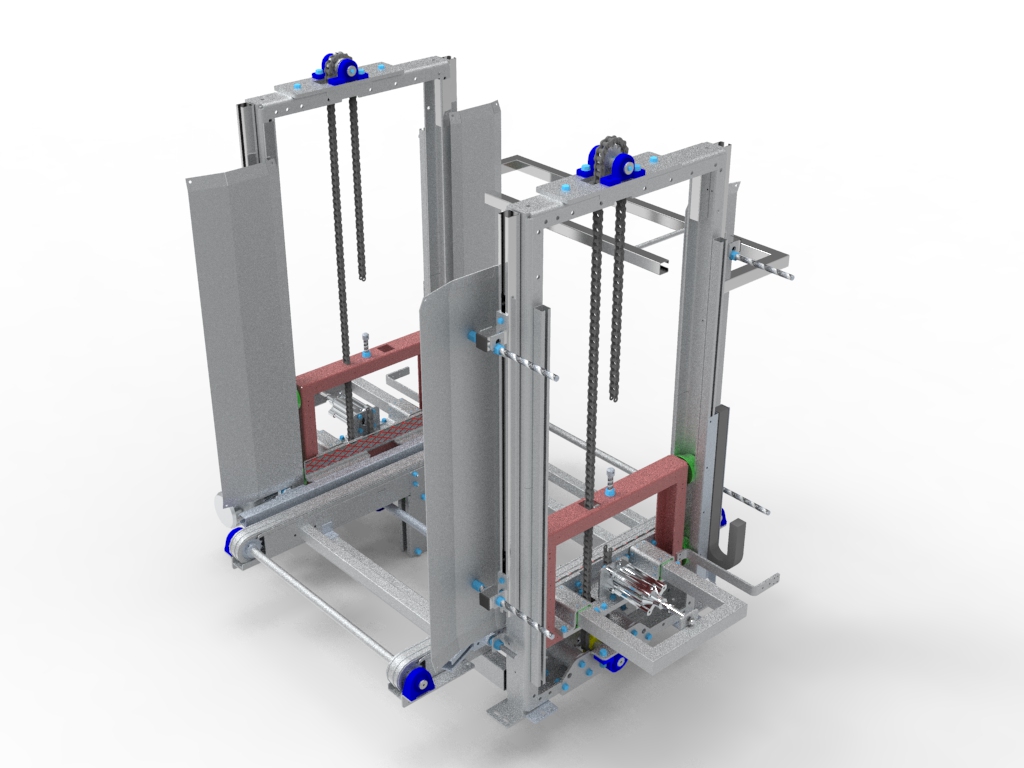

Machine Operation:

The chain conveyor individually introduces the boxes into the system. The boxes are positioned in the center of the stacking system. A pneumatic vertical cart picks up each box and maintains it at height. The next box enters the central position of the system. The first box is placed on top of the second box, starting the stacking process. The process repeats, stacking boxes one on top of the other until the desired height is reached.

Transport Speed:

- The transport speed is adjustable according to process needs, allowing precise control of product flow.

- The speed adjustment is done via a mechanical variator, facilitating adaptation to different types of products and operational requirements.

Electrical Panel:

- Equipped with an electrical panel that centralizes all control and operation functions of the machine.

- Includes a touchscreen and control buttons, facilitating easy and efficient operation.

- The user interface is designed to be intuitive and easy to use, allowing quick and precise adjustments to the stacker's settings.

Safety and Maintenance:

- The stacker is designed with safety measures to protect both the operator and the product.

- The main components are easily accessible, facilitating maintenance and minimizing downtime.

Dimensions

| Length (mm) | 1000 |

| Width (mm) | 1320 |

| High (mm) | 1800 |

| Weight (mm) | 350 |

| Area (m²) | 1,32 |

Consumption

| Electric (kW) | 1,11 |

| Air (l/h) | 1 |

| Pressure (Bar) | 7 |

| Gasoil (l/h) | |

| Gas (m³/h) |

ABOUT US

More than 35 years of specialized engineering in the horto fruit sector.

CONTACT US

Telephone: +34 962 801 391

Address: C/ El Parral, nº 10 - 46722 Beniflá (Valencia) España

Email: tecnovill@tecnovill.com

.jpg)