+34 962 801 391

OUR PRODUCTS

TECNOVILL has extensive experience in the design and manufacture of machinery, specialized in the fruit and vegetable sector.

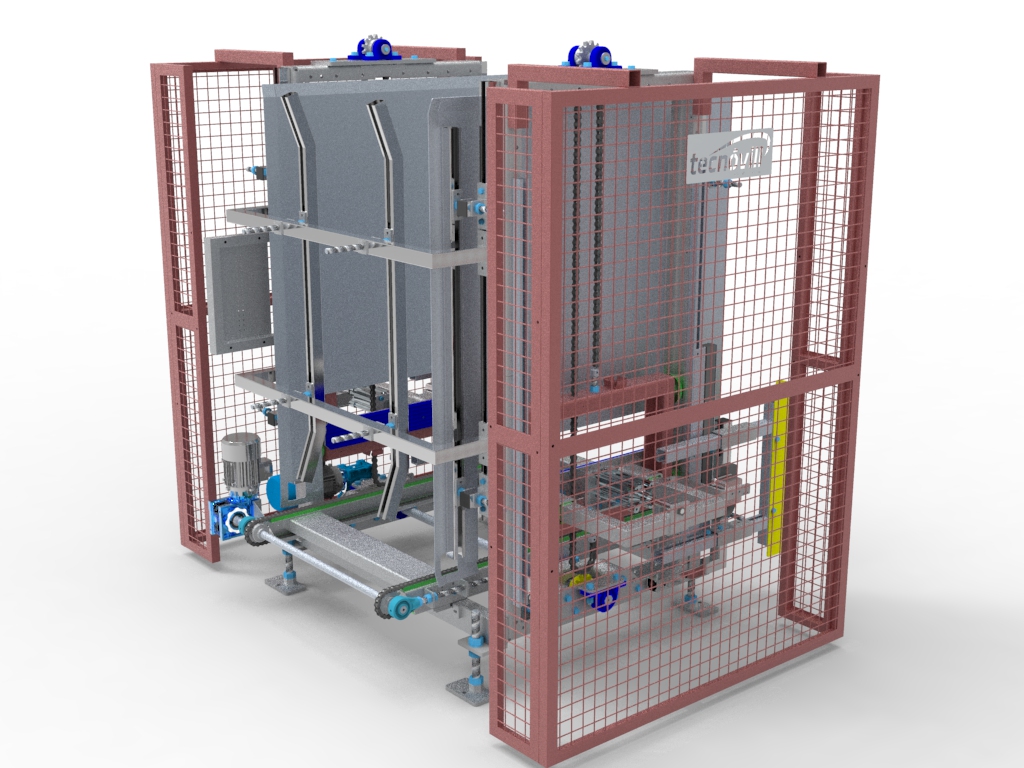

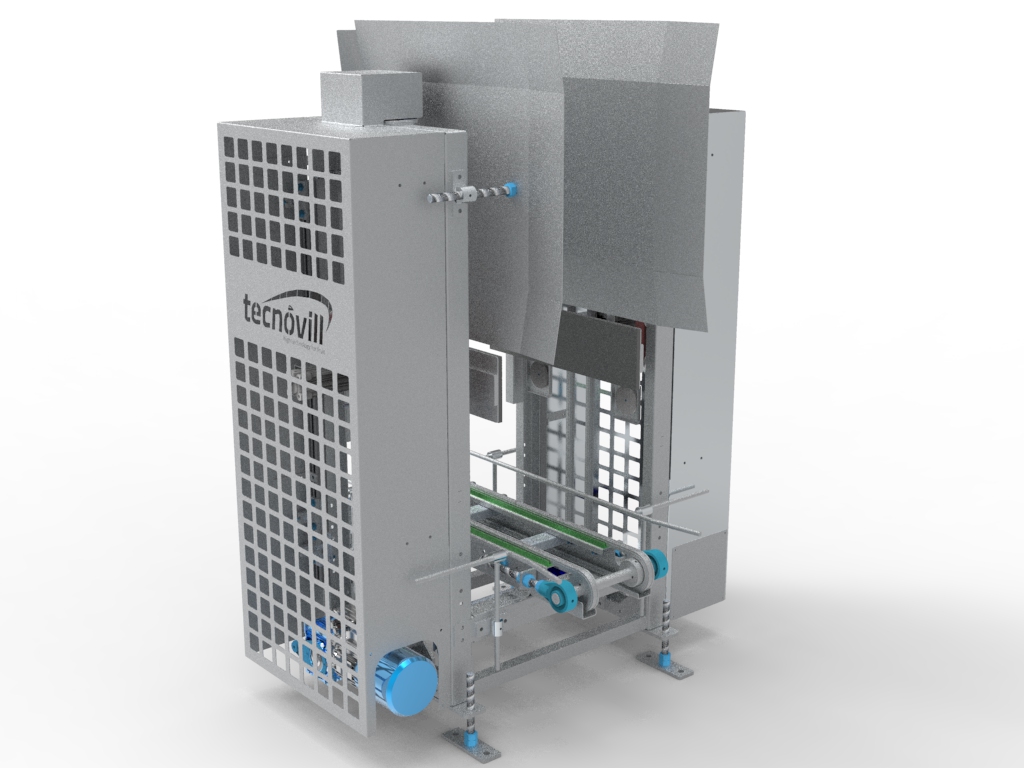

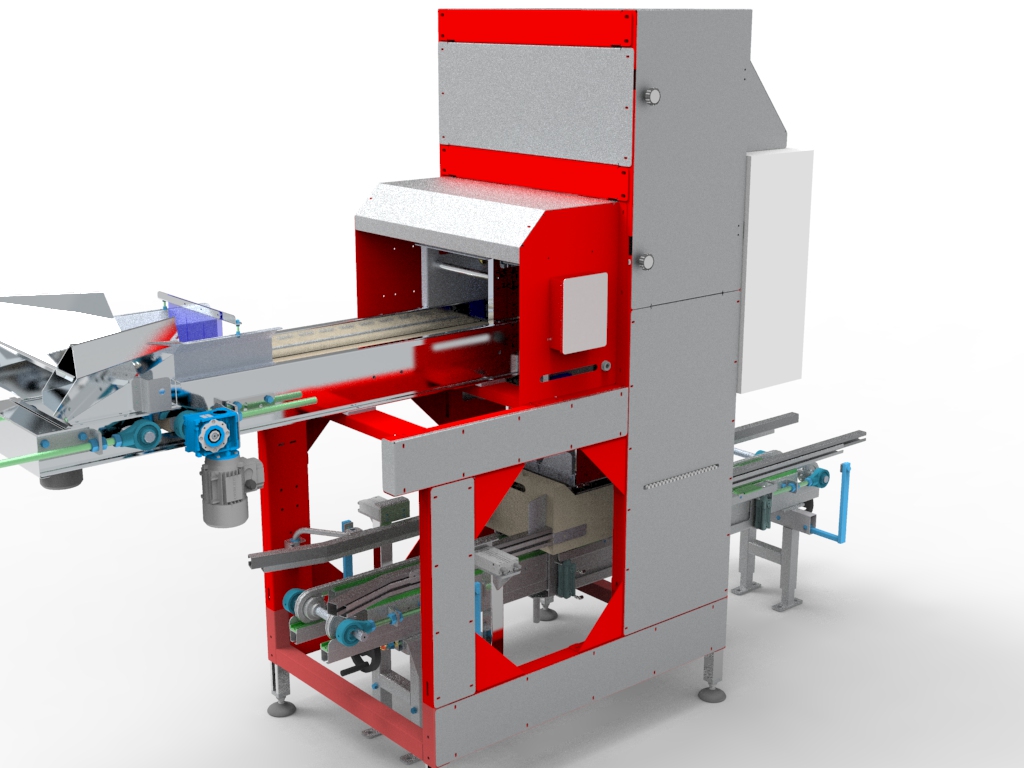

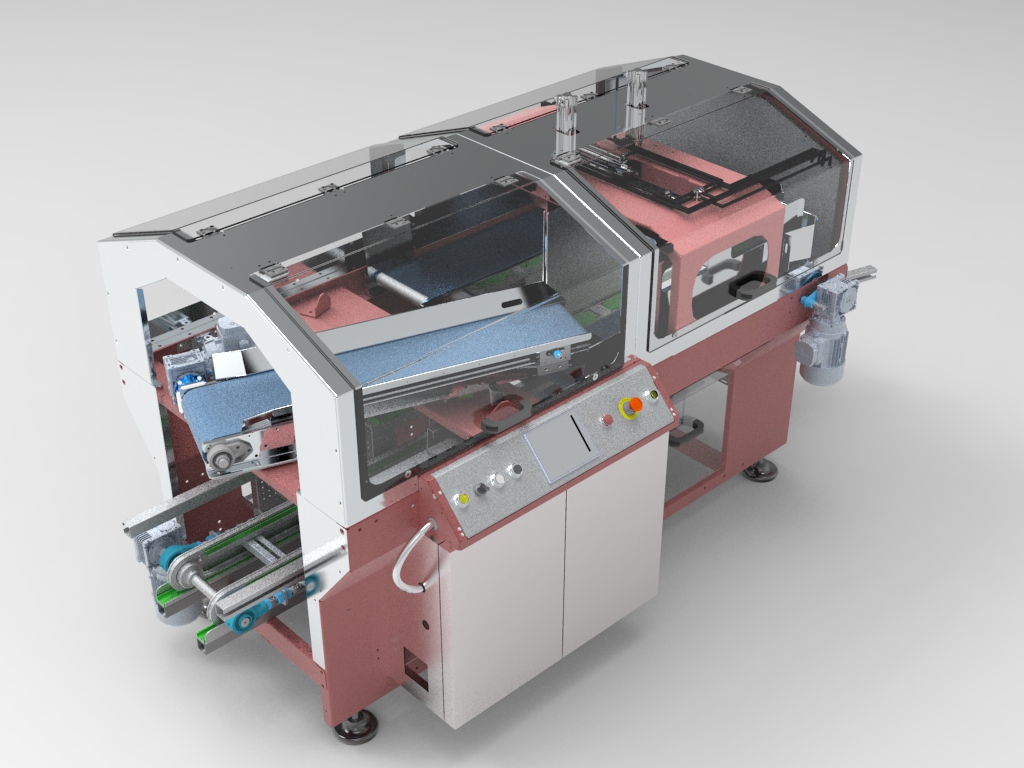

AUTOMATIC CASE PACKER FOR FRUIT EF-30

AUTOMATIC CASE PACKER FOR FRUIT EF-30

DESCRIPTION

FEATURES

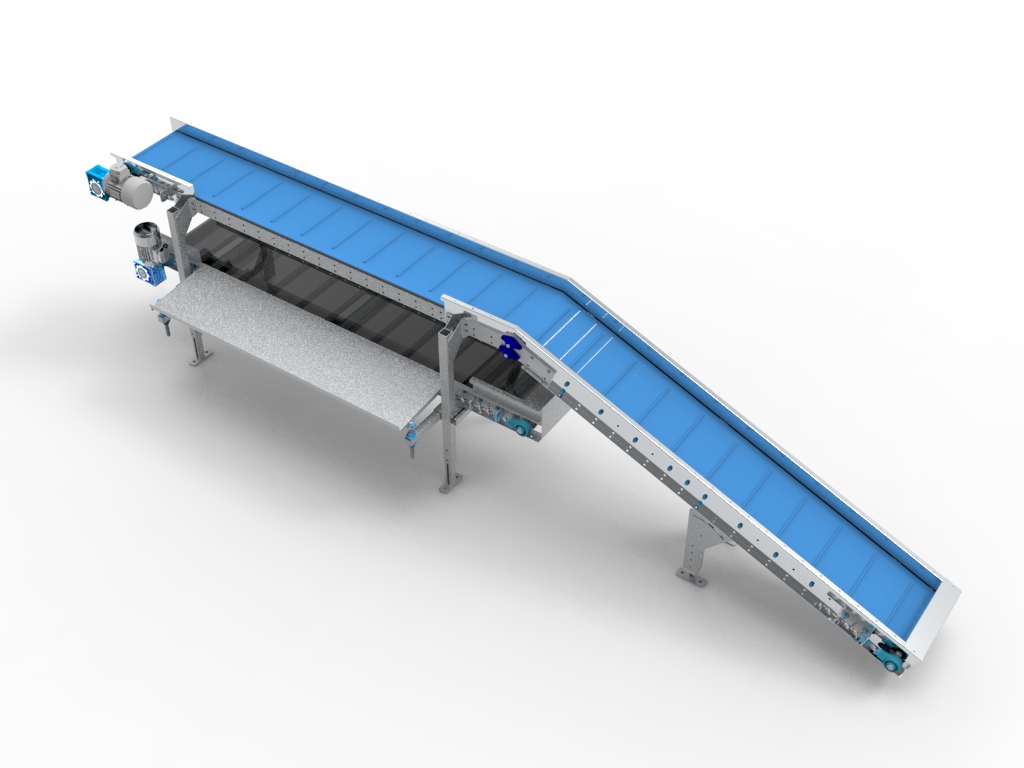

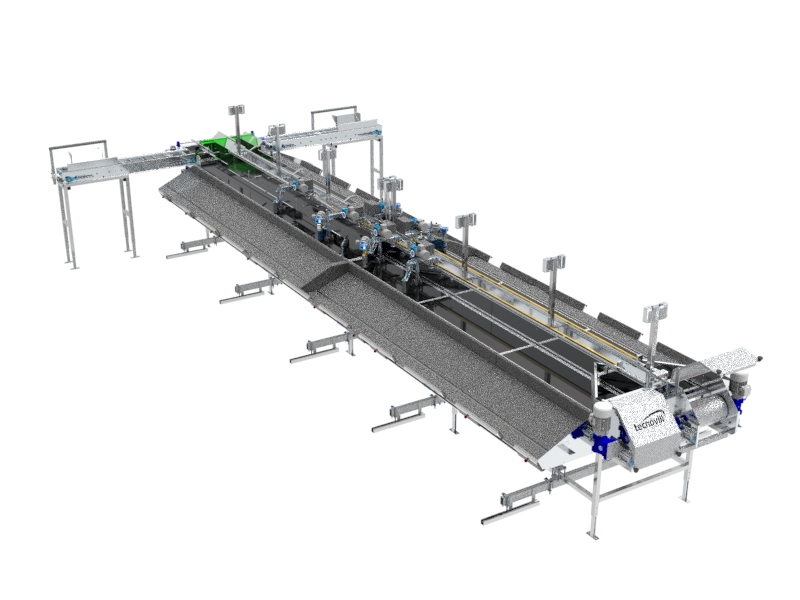

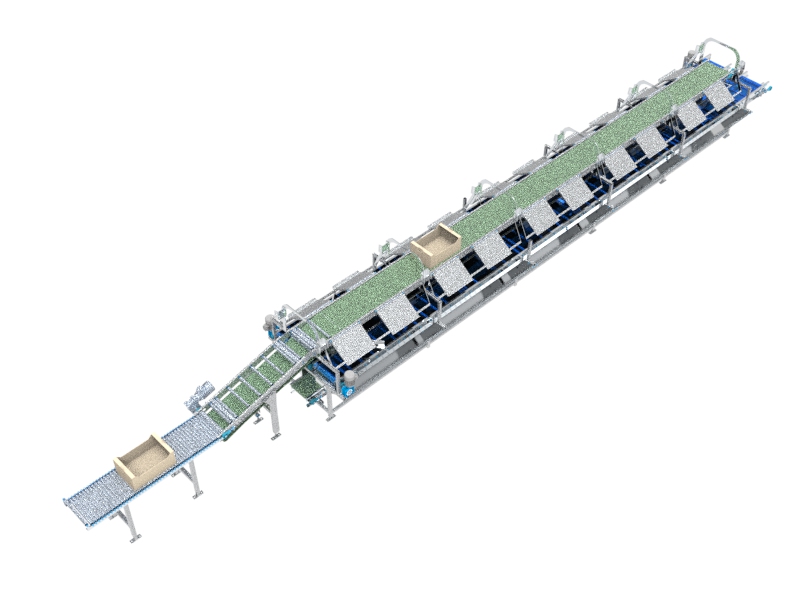

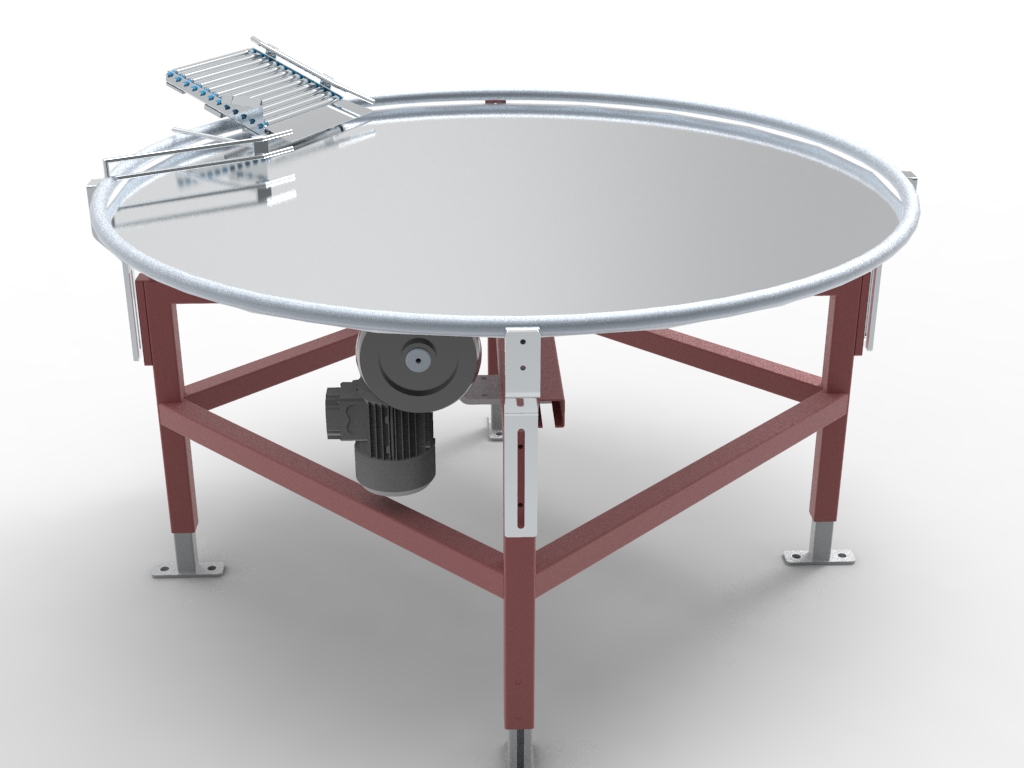

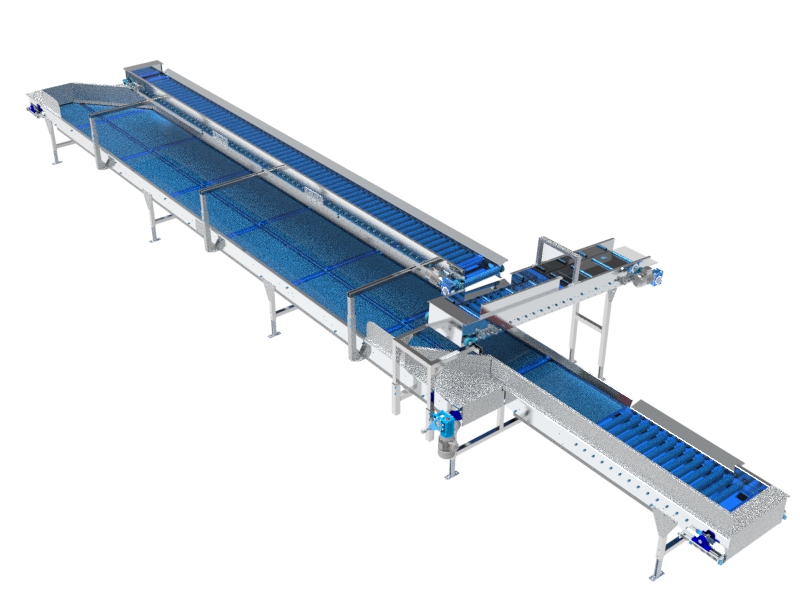

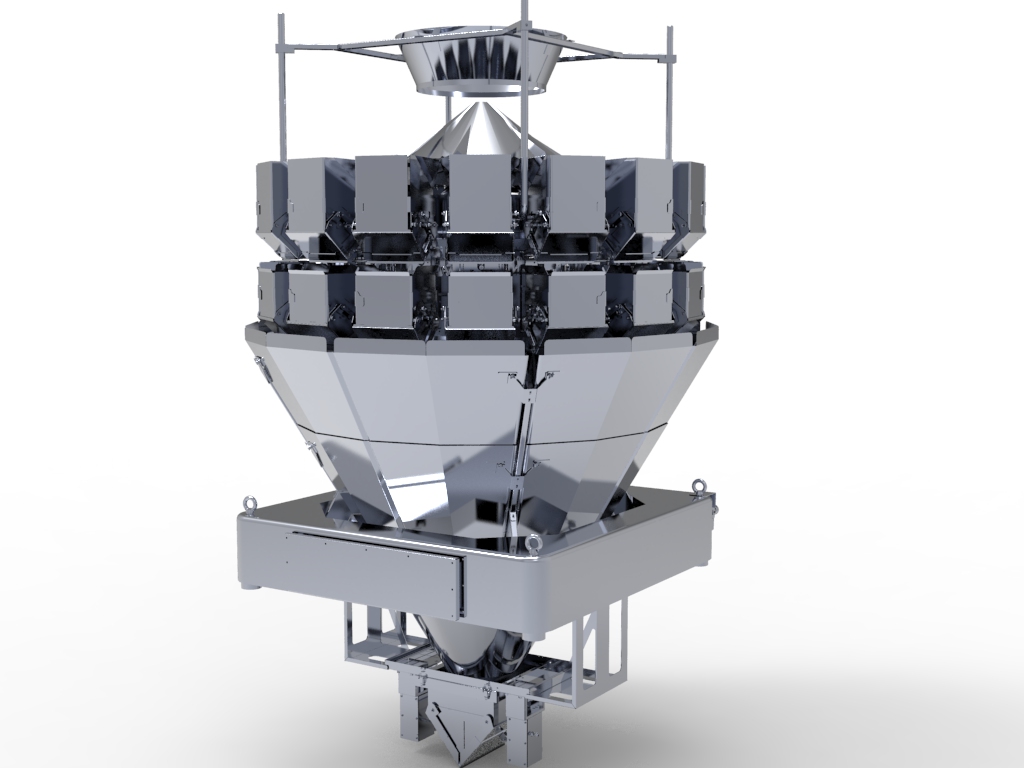

RELATED PRODUCTS

PDF

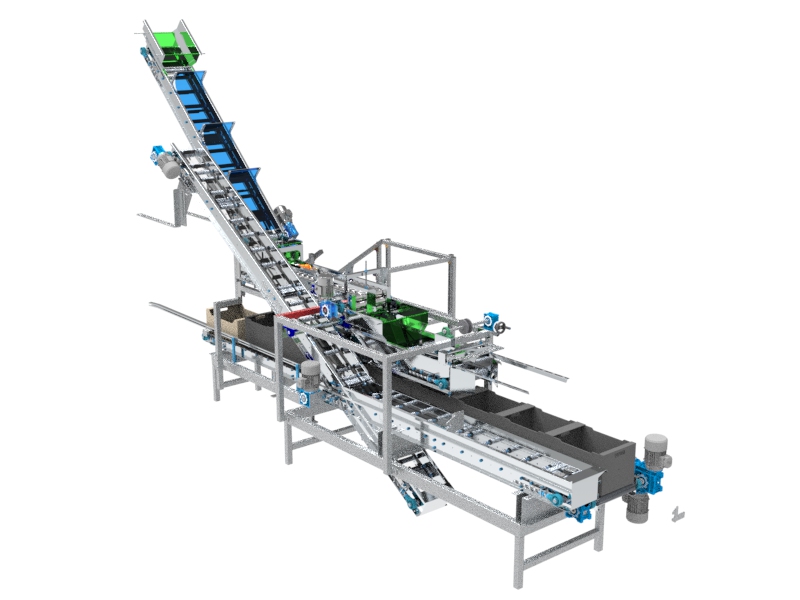

The Automatic Fruit Packing Machine is designed to automatically pack fruit into boxes in a homogeneous manner, ensuring efficiency and precision in the packaging process.

Structure:

- Constructed of painted steel, galvanized steel, and stainless steel AISI 304 in the product contact areas.

- The combination of these materials ensures durability, corrosion resistance, and a robust structure to withstand the demands of the industrial environment.

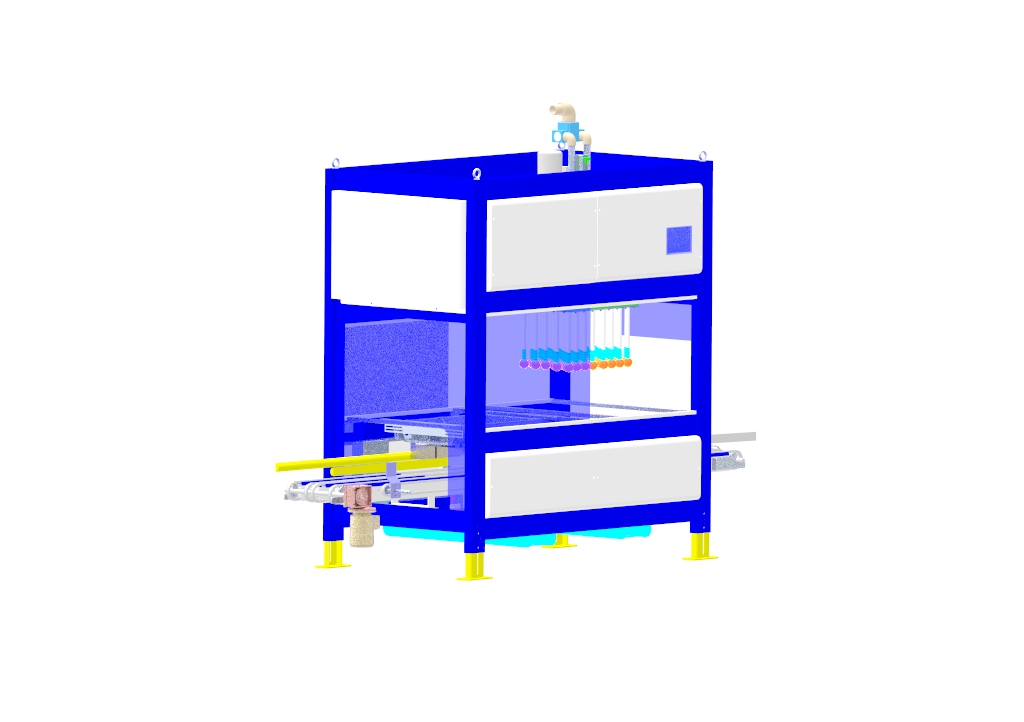

Machine Operation:

- The product is first deposited into trays, where manual assistance is required to ensure proper placement.

- A suction cup system grabs the product from the trays and places it homogeneously into the boxes.

- The packer can handle various box formats, providing flexibility in the packaging process.

- Once the packing is complete, the boxes are extracted via a chain conveyor, ensuring a continuous and efficient flow.

Transport Speed:

- The transport speed is adjustable according to process needs, allowing precise control of product flow.

- The speed adjustment is done via a mechanical variator, facilitating adaptation to different types of products and operational requirements.

Electrical Panel:

- Equipped with an electrical panel that centralizes all control and operation functions of the machine.

- Includes a touchscreen and control buttons, facilitating easy and efficient operation.

- The user interface is designed to be intuitive and easy to use, allowing quick and precise adjustments to the packer's settings.

Safety and Maintenance:

- The packer is designed with safety measures to protect both the operator and the product.

- The main components are easily accessible, facilitating maintenance and minimizing downtime.

Dimensions

| Length (mm) | 2080 |

| Width (mm) | 1210 |

| High (mm) | 2520 |

| Weight (mm) | 800 |

| Area (m²) | 2.52 |

Consumption

| Electric (kW) | 1.1 |

| Air (l/h) | 1 |

| Pressure (Bar) | 7 |

| Gasoil (l/h) | |

| Gas (m³/h) |

ABOUT US

More than 35 years of specialized engineering in the horto fruit sector.

CONTACT US

Telephone: +34 962 801 391

Address: C/ El Parral, nº 10 - 46722 Beniflá (Valencia) España

Email: tecnovill@tecnovill.com

© TECNOVILL Legal notice and Privacy policies.

.jpg)